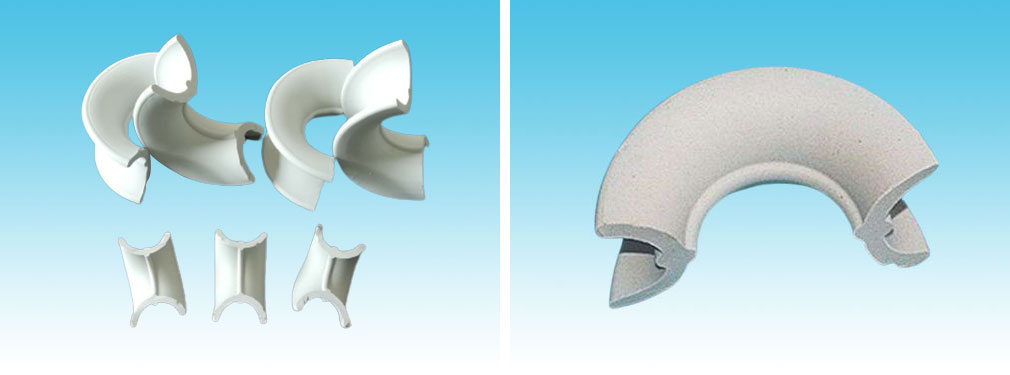

Ceramic rectangular saddle ring packing is shaped like a saddle, so many users also refer to it as a type of saddle packing. Due to the shape characteristics of the fillers, they are packed in an overlapping state inside the tower, forming a chain structure and arc-shaped air passage, which is conducive to the uniform distribution of gas-liquid flow and reducing flow resistance, and also increases the porosity of the fillers. Compared with the ceramic Rasch ring, the surface utilization rate of the fillers is also greatly improved. At the same time, it has very good bed stability and reduces the lateral pressure on the tower wall. The rectangular saddle ring is processed using a continuous extrusion process, which has the advantages of high flux, reduced pressure, and high efficiency compared to the same material of Rasch ring packing. Compared to the Bauer ring, it has lower resistance, higher flux, higher efficiency, and better packing strength and rigidity, making it a widely used loose packing material. The rectangular saddle ring packing bed has a large porosity, and there are mostly circular liquid channels inside the bed, which reduces the resistance of gas passing through the bed and also reduces the radial diffusion coefficient when the liquid flows downwards. The shape of the ceramic rectangular saddle ring lies between the circular and saddle shapes, thus combining the advantages of both. This structure is conducive to liquid distribution and increases the flow of gas. Ceramic saddle rings have high density, excellent acid and heat resistance, and can withstand corrosion from various inorganic acids, organic acids, and organic solvents except for hydrofluoric acid.

The rectangular saddle ring can be widely used in drying towers, absorption towers, cooling towers, washing towers, regeneration towers, etc. in industries such as chemical, metallurgical, and gas.

Geometric characteristics data of ceramic saddle ring packing:

| Specifications(mm) | Diameter x Height x Thickness(mmxmmxmm) | Specific surface area(m2/m3) | Void rate(m3/m3) | Stacked quantity(n/m3) | Stacked weight(kg/m3) | Dry packing factor(m-1) |

| φ16 | 16x12x3 | 378 | 0.71 | 26990 | 686 | 1055 |

| φ25 | 25x20x3 | 200 | 0.77 | 44000 | 580 | 434 |

| φ38 | 38x30x4 | 138 | 0.80 | 18500 | 540 | 252 |

| φ50 | 50x42x5 | 115 | 0.78 | 7800 | 510 | 213 |

| φ76 | 76x53x9 | 86 | 0.75 | 2400 | 537 | 179.4 |

Home

Home Tel

Tel Product

Product